Production Fluid

Increases Production – Reduces Wear – Decreases Maintenance Costs

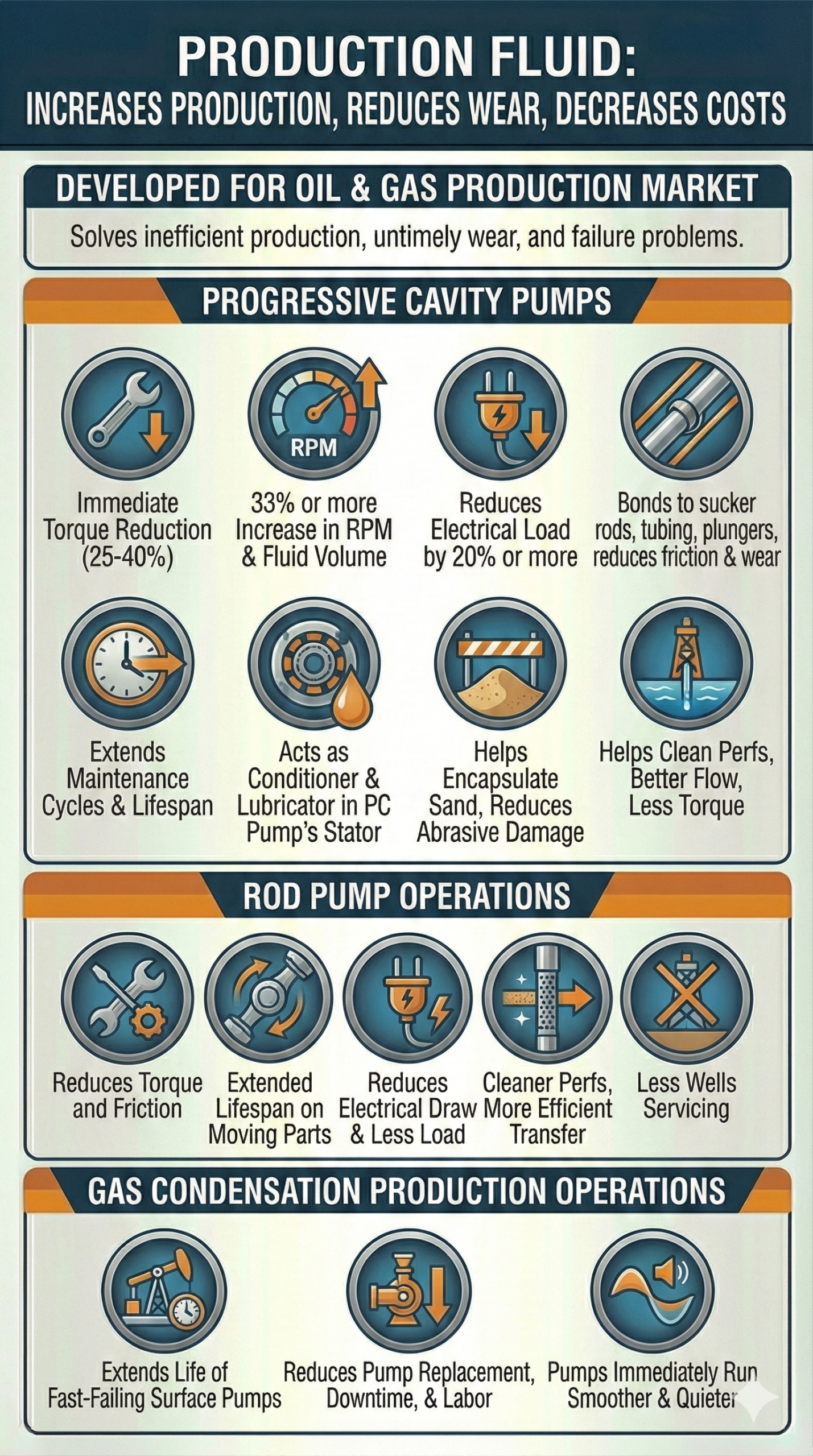

Developed for the Oil & Gas Production market to solve the problem of inefficient production and untimely wear and failure.

Progressive Cavity Pumps:

Rod Pump Operations:

Gas Condensation Production Operations: